Groundbreaking news once again emerges from the laboratories of Royal Van Wijhe Verf in Zwolle. The paint manufacturer has succeeded in developing a biobased alkyd paint that comes close in performance to Van Wijhe’s showpiece, the LBH SDT Ultra High-Gloss Paint. All while maintaining quality and extremely good outdoor durability. The BIOmotion70, the working name of this Concept Paint, consists of 70% renewable material. This is unique in the market.

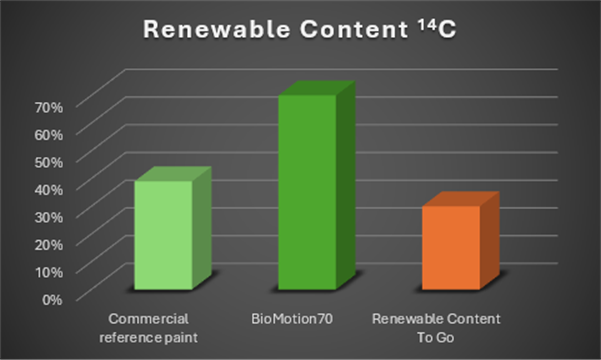

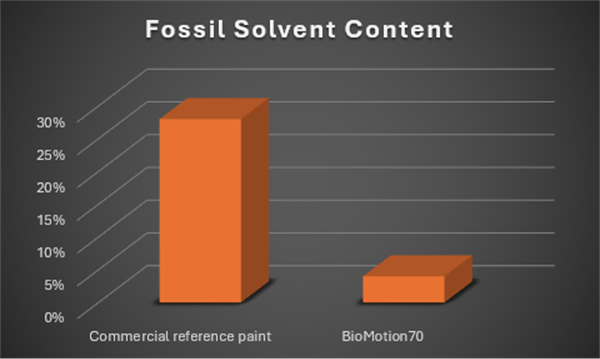

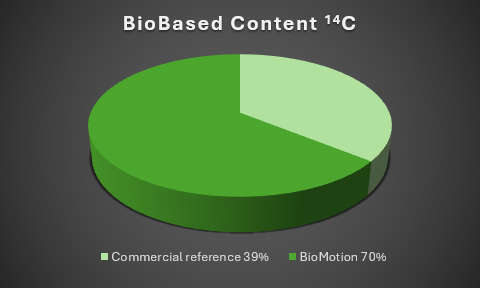

Marlies van Wijhe, CEO of Royal Van Wijhe Verf, explains enthusiastically: “We aim to present a new Concept Paint every year. We want to get the market moving and get it used to more sustainable paints. With BIOmotion70, we achieve an 85% reduction in fossil solvent. Only 4% of that remains. This paint, with a reduction of the fossil content of approximately 50%, is a major step towards a fossil-free (paint) world.”

Raw materials

In the Van Wijhe laboratories, innovations are being made to make the paint industry more sustainable, as Ron Hulst (R&D manager) explains. “We’re constantly looking for Green Deal-worthy raw materials. Raw materials that are biobased/biogenic and biodegradable, circular and less harmful to the environment. This transition requires a lot of effort and time. In chemistry, the ‘old’ knowledge is based on fossil raw materials with oil as a basis. Innovation in our industry is of high technical complexity, it takes years of searching and working on alternative raw materials. That is where the challenge lies for us. And in chain collaboration, together we achieve more. The secret of BIOmotion70 lies in a biobased molecule developed by raw material producer Relement in years of collaboration with TNO. Together with binder manufacturer Worlée, we have succeeded in incorporating this element into our recipe and further combining it with a ‘green’ solvent. Classic paint contains almost 30% solvent, which is completely petrochemical. In BIOmotion70, this is only 4%. This has been achieved by using a specially developed binder in combination with a 100% biobased solvent which is also 100% biodegradable in water and carbon dioxide.”

Wil van Meer, sustainability advisor Worlée: ‘Just as Van Wijhe is a leader, we are a frontrunner in the development of greener binders. Worlée’s R&D department has succeeded in replacing a fossil acid component in our alkyd resin with a green component developed by Relement. The paint composed in this way is not only clearly greener but also produces a better product. The result of a fruitful collaboration.’ ’

Why Alkyd?

Alkyd paint has been around for 100 years. In recent decades, the industry has done a lot to reduce the number of harmful substances. Why now an alkyd-based Concept Paint? Marlies van Wijhe responds strongly: “The whole world seems to be switching to water. But water also has its downside. The availability of clean water is not unlimited. We still know little about the long-term preservation of water-based products. I’ve always said I don’t want to put all my eggs in one basket. The synthetic market remains important. With BIOmotion70 I want to bring some excitement to this market. BIOmotion70 is currently achieving a 3-star ‘OK Biobased’ rating. That’s unique in the market. And we haven’t stopped developing yet. I consider a 4-star rating feasible.”

Monique Wekking, CCO and co-founder of Relement: ‘To produce a high-quality alkyd paint, a fossil acid component is required in the binder. Our bio MPA product is a unique biobased alternative. We’re pleased that bio MPA makes a paint with a drastically lower solvent content possible, further reducing the environmental impact. We look forward to continuing our partnership and making waves in the market.

BIOmotion70 in practice

Eric Deen, laboratory manager, explains how the right balance was sought between using as many renewable raw materials as possible on the one hand and maintaining extremely good outdoor durability on the other. “BIOmotion70 contains approximately 70% renewable material according to the carbon 14 method. That method measures what’s actually in ‘the pot’. We have tested the paint extensively. Drying, processability, flow and other properties are in line with current solvent-borne systems. The paint provides the ‘bulging gloss’ that is so desired by painters. We tested outdoor durability with rapid ageing. This is better than the known market references and it approaches the quality of our LBH SDT Ultra High Gloss Paint. BIOmotion70 protects for up to 10 years.” Marlies van Wijhe adds: “It’s a high-quality paint. It doesn’t come at the expense of performance. BIOmotion70 has a fractionally lower outdoor durability compared to our LBH SDT Ultra High Gloss Paint but is much less harmful to the environment. I find that acceptable. Does the market think so too? Is this something the market needs to get used to and will get used to?”

Further research

“We’ll soon be putting the paint into practice. We want to learn from the painters’ experience. And as stated, this BIOmotion70 has not yet been fully developed. Further research is needed. There is a lot of internal brainstorming going on here about the next steps, also with our collaboration partners Relement and Worlée. In the foreseeable future, we see opportunities to further develop this paint into a BIOmotion80, i.e. composed of 80% renewable material.” Ron Hulst: “We continue to work on the paint or paints of the future. We anticipate changing laws and regulations, we have the Green Deal 2030 in mind and also focus on other products, such as export. In Groningen, we mainly look for connections and interfaces with knowledge institutes, in Zwolle, we mainly look for this with suppliers and partners in the chain. These parties are now also on the move, which is important. It’s great that Royal Van Wijhe Verf is the leader and driving force in this but ultimately, sustainability is something you do together.”

Marlies van Wijhe, CEO of Royal Van Wijhe Verf, on the Concept Paint phenomenon: “It started as a Friday afternoon experiment. I asked Ron Hulst the R&D Manager whether the idea of Concept Paint appealed to him. It’s similar to concept cars in the automotive industry. First to demonstrate internally what we’re capable of. To show that we’re on our way. To interest suppliers of raw materials and to strengthen each other. To set something in motion. For the same reason, we’re now introducing our new paint in this concept form. Last year, it was the Flower Power wall paint, this year it’s the BIOmotion70. We invite people or parties who are involved in innovation, or who want to contribute in any way, to join us. Together we achieve more. We’re excited about a sustainable and climate-neutral future. That’s why we’re happy to share what we’re doing in the lab to make that happen. Like our groundbreaking developments with Concept Paint.”